Time:2025-09-27 Views:0

The price of switching power supplies is influenced by a complex interplay of factors that span design, manufacturing, and market dynamics. Firstly, power rating is a primary determinant: higher wattage units (e.g., 1000W+) require more robust components like larger transformers, heat sinks, and high-current capacitors, driving up production costs. Conversely, low-wattage supplies (e.g., 50W) with simpler circuitry are generally cheaper.

Secondly, component quality plays a critical role. Premium brands often use high-grade materials such as Japanese electrolytic capacitors (known for longer lifespans) and military-grade semiconductors, which resist temperature fluctuations and voltage spikes. These components cost significantly more than generic alternatives, reflected in higher retail prices. In contrast, budget-friendly models may use lower-quality parts to cut costs, risking reduced efficiency and reliability.

Efficiency standards also impact pricing. Supplies certified for 80 PLUS Platinum or Titanium efficiency undergo rigorous testing and require advanced circuit designs to minimize energy loss. These engineering complexities increase manufacturing expenses, making them pricier than non-certified or 80 PLUS Bronze models. Additionally, regulatory compliance—such as meeting safety standards (UL, CE) or environmental regulations (RoHS)—adds testing and certification costs, which are passed to consumers.

Market factors like brand reputation and supply chain stability further affect prices. Established brands with a history of reliability (e.g., Mean Well, Delta) often command a premium due to trust and after-sales support. Meanwhile, global chip shortages or fluctuations in raw material prices (copper, aluminum) can disrupt production, leading to price hikes. Finally, customization for specific industries (medical, aerospace) introduces unique design costs, making bespoke units far more expensive than off-the-shelf options.

Read recommendations:

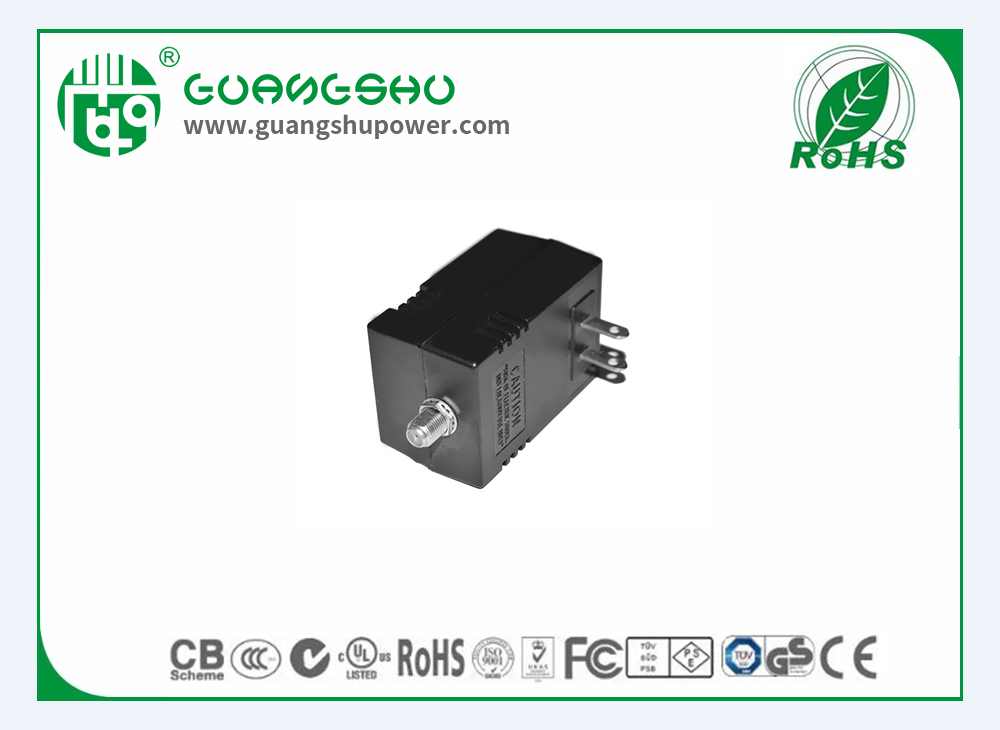

10W Wall Plug US Plug Switching power supply